About PCB copper Blistering question

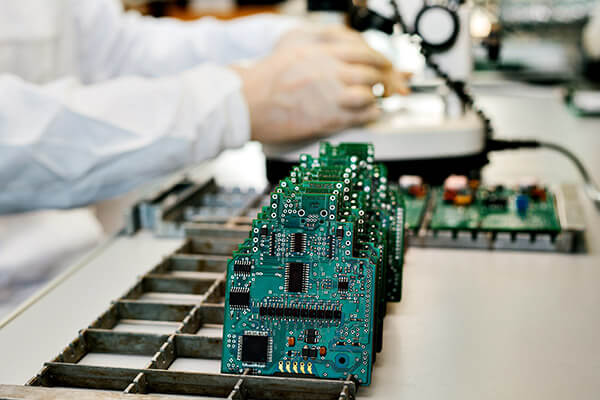

The normal PCB is to be Multibondbefore Lamination, increase the roughness of copper foil, prevent the laminated plate from bursting after pressing with PP

Surface exposed copper plating immersion will be happen Blistering?how about the ENIG adhesive force?

Surface of exposed copper area make immersion gold ,because of gold It’s very active .In order to prevent the diffusion of gold into the copper does not play a role in protecting the copper surface,Usually plated nickel on the surface of the copper, and then a layer of gold is made on the surface of the nickel. If the gold layer is too thin, the nickel layer will be oxidized, leading to the black disk effect during welding, and the solder joint will crack and fall off,If the gold thickness reaches 2U “and above, this undesirable situation will not appear basically.

Subsidence area is usually done by gong machine control of deep, generally if only control the depth and inaccurate to which layer, cost is basically consistent, if you want to which layer, you need to open the way to make with steps, namely the layer, graphic design, after pressing production by means of laser or milling cutter to open the lid, the cost increased

When the temperature in the press reaches above its Tg, over a period of time, it will slowly change from solid to glass, that is, into the shape of glue. This is not true. In fact, TG above is a high elastic state, and TG below is a glass state. That is to say, the plate at room temperature is glass state, higher than Tg into high elastic state, deformation can occur.

There may be a misunderstanding, but when I wrote the article I called it gelatinous just to make it easier for you to understand. In fact, the so-called PCB Tg value refers to the critical temperature point when the substrate melts from solid state to rubberized liquid, and Tg point is the melting point.

The glass transition temperature is one of the characteristic marks of polymer. With the glass transition temperature as the boundary, the polymer expresses different physical properties: below the glass transition temperature, the polymer material is the molecular compound plastic state, above the glass transition temperature, the polymer material is the rubber state……

From the point of view of engineering application, glass transition temperature is the maximum temperature of engineering molecular compound plastics and the lower limit of rubber or elastomer application.

The higher the Tg value, the better the heat resistance of the plate, the better the deformation resistance of the plate

How is the redesign designed?

To plan, can use inside the graphics to make the whole layer, and the board when forming the inner lining of the graphics in open way milling, similar to combine hard and soft board, the process is more complex, but the inner layer of copper foil is on the core board pressing from the beginning, don’t like control deep went up again after plating, bonding force is bad.

See copper plating requirements, plate factory does not remind? Gold plating, copper plating must be asked

It is not said that every time the control of deep copper plating will bubble, this is a probability problem, if the substrate copper plating area is relatively small, it will not bubble, such as the copper surface on the POFV does not exist such problems. If the copper plating area is large, there is this risk