How Do I Prep My PCB for Fabrication Accelerating PCB Assembly

1.Double Check Footprints and Packages

2.Go for a Large Selection of Tested Part Substitutions

A common delay in production occurs when key parts are unavailable and no substitutions have been pretested and approved. If a part has viable substitutions but is in a critical path of your circuit or product, I highly recommended you build prototypes and test with each substitution before going to production. This reduces the risk involved when switching to a substituted part in the future.

If you have unique parts that do not have any direct substitutes (microcontrollers, specialized sensors, etc.) check on the part lifetime from the manufacture of the part. Manufacturers will mark components slated to be discontinued as “Not Recommended for New Designs”.

Typically, manufacturers guarantee a set life span for manufacturing the part and will notify users of the part when it will be End of Life’d (EoL). Make sure the part you need will be available until the end of your product’s production life span in order to help prevent costly product redesigns down the road.

3.Utilize Pre-Certified Radio Modules

4.Consider Your Wireless Antenna Layout

5.Don’t Forget the Decoupling Capacitors

6.Protect Your Board with Proper Trace Width and Spacing

7.Choose the Right Power Supply Regulator Routing

8.Working with Linear Regulators

9.Working with Switching Regulators

10.Include Thermal Relief for Large Copper Traces and Pours

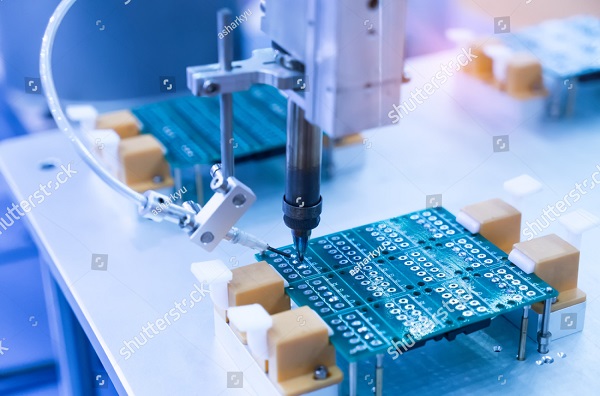

11.Optimize Your Design for SMT Assembly

12.Double Check Your Design Rule Checks

Double checking your design rule checks is probably the most important item on this list. Check with your manufacturer on their design rules. Most manufacturers have different levels of scaling design rules. If you can get away with the larger and more standard design rules you should.

Before sending your design files to your manufacturer I suggest you run your DRC one last time and check the following things:

- Run a design rule check (DRC)

- Check connections and routes

- Use your EDA tool’s “airwires” or “rat lines” to visually show which part pads are connected to each other on a signal net