SMD LED PCB BOARD ASSEMBLY SERVICE

The use of LED PCB assembly has greatly impacted the lighting industry, making it a popular choice for various lighting needs. Its superior technology is constantly progressing due to the high demand for LED Light Circuit Board Assembly.

Due to advancements in LED technology, the demand for LED circuit board assembly has significantly increased. This is due to the enhanced durability, longevity, and performance of LED PCB assemblies. As a result, LED lighting has become the preferred choice over traditional fluorescent and incandescent lamps.

Initially, LED lighting was not widely used due to the need for high heat dissipation. This was because the PCB would often overheat and cause the LEDs to fail. However, with the use of metal core PCBs made from materials like Aluminum and Copper, heat dissipation is no longer a concern. These types of PCBs are able to efficiently dissipate heat and lower the temperature of the board, even without heat sinks. Aluminum PCBs are a popular choice for LED lighting due to their affordability and impressive performance.

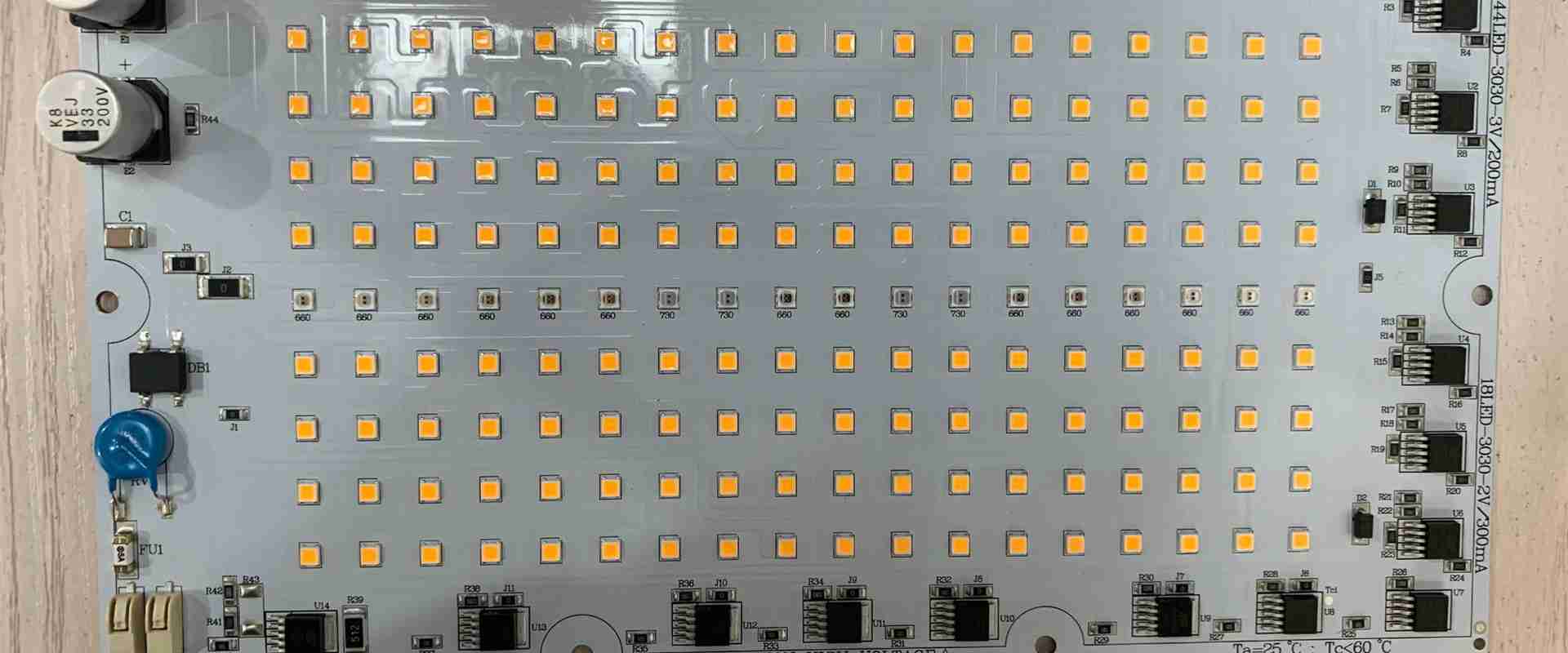

LED PCB

As printed circuit board technology has continued to evolve, it has paved the way for the creation of a host of exciting product innovations. A prime example is the development of the PCB for LED lighting. The LED is soldered to the circuit board and features a chip that produces the light when electrically connected. A thermal heat sink and a ceramic base are used to bond the chip.

Now SMD packaging type is the most widely used packaging form in LED applications. In general, it’s limited for the light emitted from a single LED component. So multiple LED components would be used for a single light fixture to achieve sufficient light. Like other semiconductor devices, PCB is the best method to electrically connect the LED components. And a PCB with LED components soldered is usually called as “LED PCB”.

If leds are integrated into a circuit board, it is easier to combine LED thin-film switches with keyboards, touch screens and other types of thin-film switches. Even when creating complex backlit switch components, built-in or embedded LED PCBS provide greater design freedom. The small thickness of LED film switches reduces the total area of these complex switch interfaces. Designers and engineers often choose integrated LED PCBS when checking and updating products.

In general, LED PCBS provide the most convenient backlight for membrane switches. Sometimes they are a better choice for small ICONS and symbols for backlighting, as larger ICONS and even backlighting with embedded LED PCB circuitry are not so easy to achieve.

Consumer Electronics

Consumer electronics are those devices that are being used by humans on a daily basis. These electronics include smartphones and computers, in fact, even the new forms of fridges also have electronic components in them. The best part about the LED PCBs is that they offer low units per cost which make the price of the final product relatively less than what it’s supposed to be.

Medical

Lighting tools used in surgeries and medical examinations commonly use high-powered LED lights, and these LED lights often use aluminum PCBs.

This is primarily due to the durability and heat transfer capabilities of aluminum PCB LEDs — this ensures medical equipment is functioning properly regardless of the number of patients cycling through a medical office. In addition to lighting tools, medical scanning technology often uses aluminum PCBs as well.

WHAT IS AN LED?

LED, short for Light Emitting Diode, is a semiconductor device that emits light when current passes through it. Due to this feature, it is commonly referred to as LED. This special device produces light in the visible range, making it ideal for use in lighting applications.

LEDs are ubiquitous in a wide range of industries and fields, serving primarily as sources of light and indicators. With their versatility and potential for a variety of applications, they have become a prominent force in the market.

What is LED PCB?

LED PCB, or Light-Emitting Diode Printed Circuit Board, is a specialized type of circuit board commonly used in the production of LED lighting fixtures. Due to their high power output, LEDs produce a significant amount of heat during operation. In order to dissipate this heat effectively, aluminum is often used as the substrate material for LED PCBs due to its excellent thermal conductivity. Essentially, this means that the circuit is printed onto an aluminum plane which acts as a heat sink, allowing for efficient cooling. From there, electronic components can be easily soldered onto the board, making LED PCBs a crucial component in the production of LED lighting technology.

Factors that impact LED PCB quality include the type of aluminum used, its hardness, surface treatment, and thickness. It is crucial to select appropriate specifications based on the product’s heat generation.

WHAT IS LED PCB ASSEMBLY?

A PCB that has been fully equipped with components is referred to as PCB Assembly. If it is used for LED lighting, it is specifically called an LED PCB assembly. This type of assembly commonly includes multiple LEDs and other necessary components. It is typically constructed with aluminum in order to quickly dissipate heat. The assembly is known for its durability and strength, making it capable of withstanding wear and tear and lasting for a considerable amount of time. The buyer can request the assembly in any desired shape. Commonly, LED PCB strips, circular and rectangular boards are available.

A turnkey PCB assembly service encompasses the entire process, from component procurement to LED PCB assembly testing, by the contract manufacturer. In contrast, an LED PCB assembly service involves fabrication and component installation, but every step is still crucial.

Turnkey Service

- LED components sourcing

- LED circuit board manufacturing

- Free DFA and DFT check

- Quality control system – X-ray, AOI, FAI

- 100% Testing – Flying probe, function testing

- 100% original LED chip

- LED PCB assembly service

Capabilities

- No MOQ

- Mass production

- Competitive price

- Prototype assembly service

- LED PCB assembly up to 1.8 meter long

- 24 hours fast LED PCB assembly expedite services

At Bgpcba, we offer comprehensive turnkey services for PCB assembly. Additionally, our fast-turn prototyping service is available for your convenience.

WHY CHOOSE BGPCBA

With years of experience in China, Bgpcba is a prominent manufacturer of LED PCBs and offers the quickest turnaround times for both fabrication and assembly. Our reputation for quality and speed is unmatched in the industry.

WHY LEDS AND LED PCB ASSEMBLIES?

LED lighting has greatly reduced the need for other lighting technologies, with numerous factors contributing to its success.

Long-lasting

LEDs are known for their durability, lasting up to 25 times longer than fluorescent and incandescent lights. This makes them a popular choice, as they require less frequent replacement and save money in the long run. The efficient dissipation of heat by the LED PCB assembly is the key factor in their extended lifespan.

Compact

LEDs are compact and perfect for tight spaces. They are ideal for small areas where traditional bulbs are hard to fit. Additionally, their small size allows for seamless integration into intricate PCBAs.

LED PCB assemblies offer compact design options, with the ability to easily incorporate multiple LEDs in any desired arrangement. This design flexibility allows for a wide range of possibilities.

Efficient

LED lights are highly efficient as they do not require heat to produce light. This is due to the fact that when an electric current flows through them, light is emitted. This lack of heat production results in minimal energy loss, with only 5% being wasted and the remaining being converted to light. As a result, LEDs use less energy but can produce the same level of light as other lighting technologies. Making the switch to LED technology can lead to a significant reduction in energy costs, potentially saving you up to 90% on your energy bill.

Low Voltage Application

Optimize your lighting with LEDs, which operate effectively on low voltages and provide a safer alternative to traditional bulbs. With decreased voltage stress, LEDs are a reliable option for indoor illumination and can prevent potential issues.

Environmentally Friendly

LED technology is a safe and environmentally friendly option compared to other technologies that may contain toxic substances like mercury. This makes LED PCB Assembly a responsible choice for those concerned about the environment.

No Effect of Ambient Temperature

The LED PCB Assemblies are designed to function in any environment, regardless of temperature. They are highly adaptable and can withstand even the most extreme ambient temperatures.

LED CIRCUIT BOARD ASSEMBLY PROCESS

LED PCB Assembly follows a tried and true manufacturing process, similar to other PCB assemblies, and consisting of multiple steps.

Placement of Order

When placing an order for PCB assembly, the customer must discuss the requirements and provide all necessary files and documents, including Gerber files and BOM. Our experts at Bgpcba then perform Design for Manufacturability (DFM) to ensure feasibility. We thoroughly review the buyer’s files for any issues and make necessary adjustments before beginning the process.

PCB Fabrication

In order to successfully assemble the LED PCB, it is crucial to fabricate the PCB first. The Aluminum material used for the PCB is highly durable and aids in heat dissipation. A typical Aluminum PCB consists of three layers: a copper layer for electrical connections, a dielectric layer for heat transfer, and an Aluminum base layer.

The PCB is fabricated according to the requirements of the buyer.

Procurement of Components

To complete the PCB, you must order the necessary components from multiple vendors, which may take 3-5 days. The purchasing process is based on the BOM list and includes SMD LEDs, resistors, and other essential items.

Solder Paste on the PCB

The application of solder paste plays a crucial role in connecting components to the board. A stencil is used to apply the paste onto the bare PCB, precisely targeting specific areas. A wiper is then used to apply and remove any excess paste, resulting in precise placement and soldering of SMDs.

Pick and Place

During the application of the paste on the PCB, the next step is to precisely place the components. This process is automated and carried out by a machine, with instructions provided through a Pick and Place file that contains XY coordinates and rotation information for the PCB. The machine then accurately places the components based on these instructions. It’s important to note that at this stage, the components are simply positioned and not soldered.

Reflow Soldering

The PCB is heated in a reflow oven during the next stage, causing the applied solder to melt and create connections between the components and the board. The board is then cooled after melting to avoid any potential heat damage before exiting the oven.

Reflow soldering is commonly used for SMDs, while through-hole components are soldered manually. In the case of a one-sided PCB, wave soldering is a helpful and efficient alternative. This method involves the application of molten solder on the bottom of the PCB.

Inspection

Inspection is crucial to ensuring the performance of the LED PCB assembly, as there can be numerous issues that arise during the soldering process, such as short circuits or missing joints. Initially, manual inspection is conducted before the use of AOI (Automatic Optical Inspection), which utilizes multiple cameras at various angles to capture images of the PCB. This thorough and efficient process quickly identifies any faults or problems.

X-ray inspection is a superior method of inspection compared to AOI, as it allows for the observation of connections beneath components. By passing rays through the PCB assembly and analyzing the reflected image, this advanced technique utilizes image processing to provide accurate results.

Final Test

The PCB’s final inspection does not guarantee proper operation and expected results, even if everything is up to standard. To ensure quality, the LED PCB assembly undergoes a thorough final test using various methods such as flying probe, functionality, and reliability tests.

Get the Best LED PCB Assembly Services

As a leading manufacturer in China, Bgpcba specializes in delivering top-quality LED PCB assembly services. Our ISO, RoHS, and UL certifications ensure that our quality management system adheres to international standards. We take pride in offering efficient and reliable LED PCB assembly services, with a variety of pre-designed options available. Additionally, we excel at turnkey PCB services, handling every step of the process. For more information and details, please do not hesitate to reach out to us.

Meet the Dream Team

Textile inspires and equips people to accelerate sustainable practices in the textile value chain. We focus on minimizing the harmful impacts of the global textile industry and maximizing its positive effects.