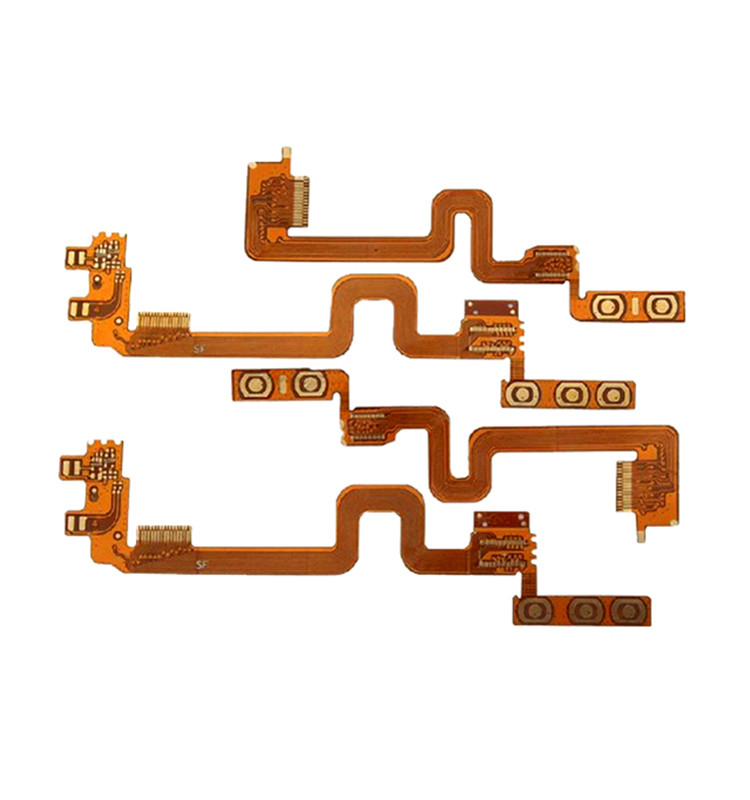

What is Flexible PCB?

Flexible printed circuit boards, also called Flexible PCBs or Flex PCBs, derive their name for their ability to enable the circuitry to be designed to fit the electronic device or product, as opposed to building the device to conform to the circuit board. Flex boards are characterized by a distinctly patterned printed circuitry and component arrangement highlighted by a malleable base material.

WHAT ARE ADVANTAGES OF FLEXIBLE PCB?

Flexible printed circuit boards offer a number of potential benefits including:

- Saving Space. Flex PCB design requires only about 10 percent of the space and weight of an ordinary circuit board assembly, offering greater installation and packaging freedom. The inherent flexibility also permits tighter bend capabilities.

- Maximum Reliability. A flexible printed circuit board requires fewer interconnects, which in turn requires fewer contact crimps, connectors and solder joints. Simply put, a flexible PCB board does not contain as many potential sources for failure, which enhances their reliability.

- Enhanced Capabilities. The flexible printed circuits boards are compatible with virtually any type of connector or component and works well with options such as ZIP connectors. They also perform extremely well in extreme temperatures and offer superior resistance to radiation and chemicals.

- Cost Savings. Cost-saving advantages of Flexible PCBs include reduced material and packaging demands, lower parts replacement costs and assembly errors that could result in the need for repairs.

These benefits make flex PCBs ideally fit for a wide range of applications in industries such as Military, Transportation, Medical, Consumer Electronics, Automotive, Aerospace, Communications and Industrial.

Meet the Dream Team

Textile inspires and equips people to accelerate sustainable practices in the textile value chain. We focus on minimizing the harmful impacts of the global textile industry and maximizing its positive effects.

Why Not Make All Circuit Boards Flexible?

Flexible circuit boards are certainly useful, but they are not going to replace rigid circuit boards for all applications. Cost efficiency is the main obstacle to implementing an exclusively flexible circuit board design in a consumer product. Rigid circuit boards are less expensive to manufacture and install in a typical automated high-volume fabricating facility.

Typically, the ideal solution for an innovative product is one that incorporates flexible circuitry when necessary and employs solid, reliable rigid circuit boards where possible to keep manufacturing and assembly costs down.

Some manufacturers even use hybrid rigid-flex printed circuit boards expressly for this purpose. This is common in laptop computers and medical devices, where rigid circuit boards can be connected to one other using ribbon-like flexible circuits. These boards can be compounded and designed to meet any number of engineering needs by focusing on the respective strengths of each circuit board base technology.

BGPCBA creates both flexible and printed circuit boards for product manufacturers. Enjoy a consultation with one of our sales reps to find out if your product prototype design is best served by flexible or rigid circuit board types.

| Feature | Capability |

| Number of Layers | 1-8 layer |

| Build Time | 3-5days |

| Polyimide base material | Polyimide Flex |

| FPC Thickness | 0.08-0.4mm |

| Min Track/Spacing | >=0.06mm |

| Min Hole Size(diameter) | >=0.35mm |

| Coverlay(Flex Part) | Yellow Coverlay,White Coverlay,Black Coverlay |

| Silkscreen Color | White,Black |

| Surface Finish | Immersion gold,OSP,Immersion silver,Immersioni Tin |

| Finished Copper | 0.5-2oz |