PCB Conformal Coating Service

PCB conformal coating is the process of applying a specialty polymeric film to protect the components in the circuit boards and other electronic parts. The polymeric film forming thickness is considered as per irregular working environmental conditions of the product . PCB conformal coatings helps protect the components against from humidity, heat, debris, aggressive chemicals, fungus, airborne contamination such as dirt and dust conditions.

BGPCBA Electronics offers conformal coatings service for low, medium and high volume PCBA board. You can apply coatings on partial key components, or complete boards with coatings.

Types of PCB Conformal Coating

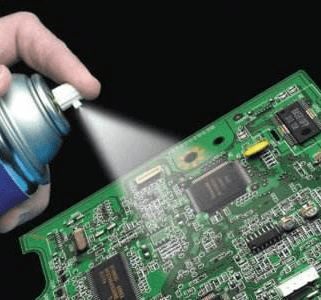

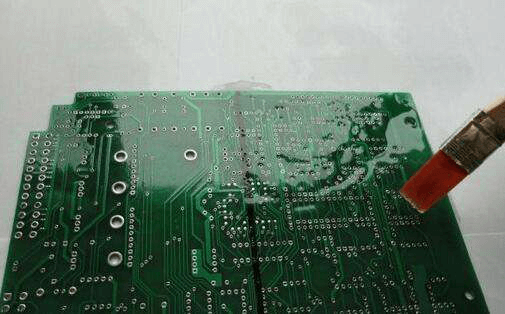

At BGPCBA Electronics, there are various types of PCB conformal coatings. The coatings are applied with the tools of brush and spray, also by dip coating.

1.Acrylic Resin: Acrylic resins are usually one type of solvent dissolvable preformed acrylic polymers. Acrylic coating facilitates easy repair work, as it gets easily dissolved in many organic solvents. The coating offers not only good fungus and humidity resistance, but also offers smooth and crystal clear finish, which makes your PCBA boards high quality and clean surface.

2.Epoxy: Epoxy resin coating is available as two part compound, and has a good abrasive, chemical, and humidity resistance. The coatings can work in temperatures up to 150°C. Epoxy coating provides a rigid coating on the surface, which offers a superior abrasive and chemical resistance.

3.Silicones: Silicone resin is a soft and flexible coating, which offers excellent corrosion resistance and chemical resistance. The coating has a low dissipation factor, which makes them suitable for high impedance circuitry. Silicone coating can work in the temperature range of 55°C to 200°C. The coating has excellent light transmission properties, which makes it ideal choice for solar applications.

Obviously, PCB conformal coating helps improve PCBA board quality and usage life. STHL PCBA has provided our customers conformal coating services to kinds of industries and applications. Our skills and experiences ensure you an excellent and reliable coating services. If any demand, please email us at sales@bgpcba.com

Painting process has the following four ways

- brush coating is common, can produce excellent on a smooth surface coating effect

- Spraying coating can be conveniently used repair and small-scale production use, spray gun is suitable for the production Yu Dagui touch, but both spraying means higher requirements for the accuracy of the operation, and may produce shadows (lower components not covered by anti-corrosion paint)

- Automatic dip coating — Dip coating can ensure complete coating, and will not cause material waste caused by excessive spraying.

- Selective coating – accurate coating and no waste of material, suitable for mass coating, but high requirements for coating equipment. The most suitable for large quantities of film mulch. Use a compiled XY table to reduce masking. Many connectors do not need to be painted when PCB is painted. Adhesive paper is too slow and there is too much residual adhesive when tearing, can consider according to the shape, size, position of the connector, do a combined cover, with the installation hole positioning. Cover areas that need not be painted.

Meet the Dream Team

Textile inspires and equips people to accelerate sustainable practices in the textile value chain. We focus on minimizing the harmful impacts of the global textile industry and maximizing its positive effects.