What is an aluminum pcb

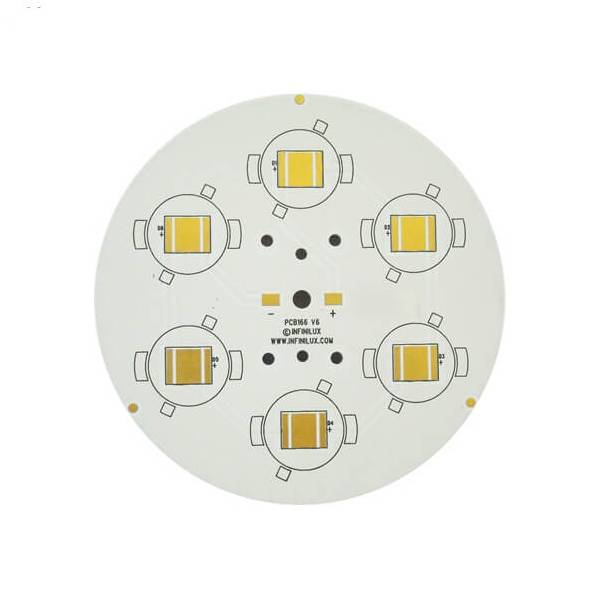

Aluminum pcb with good heat dissipation function is a kind of metal base copper-clad r.p. panel and general single panel composed of three layers structure, respectively is the circuit layer (copper foil) insulating layer and the metal base is common in LED lighting products, on both sides of the white side is welded LED pin, the other side aluminum instinctive quality, usually apply thermal coagulation pulp after contact with heat conduction part there is ceramic substrates, and so on.

LED aluminum PCB, also means printed circuit board, but the material of the circuit board is aluminum alloy, we used to general circuit board material is glass fiber, but because LED heating is large, so the CIRCUIT board used for LED lamps are generally aluminum substrate, can heat conduction fast, other equipment or electrical circuit board or glass fiber board!

What are the advantages of aluminum pcb

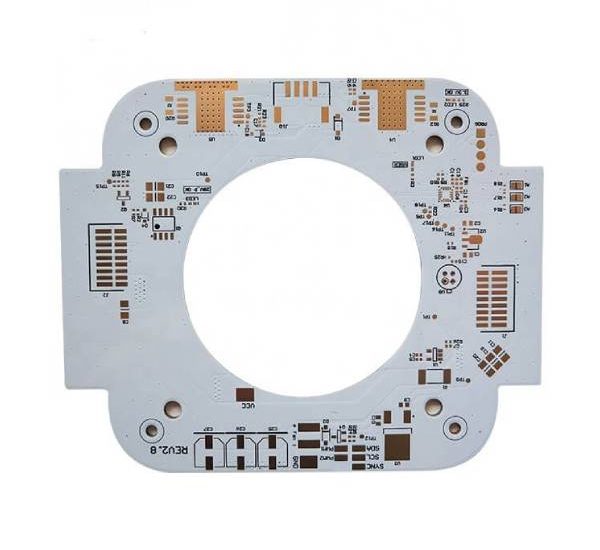

Aluminum pcb for a variety of electronic components, integrated circuits provide fixed, electronic components of the mechanical support components, is to achieve the electrical connection of the assembly plate. Aluminum based circuit board is called printed circuit board or printed aluminum based circuit board, PCB English name. The aluminum base circuit board itself is the insulation base board, the aluminum base board assembly mounting hole, the connection wire (copper), the board welding electronic component pin welding assembly. Electronic components are mounted on one side of the aluminum-based circuit board and pins are used for welding components on the other side. A layer of insulating paint is often applied to the welding surface. Both positive and negative al-based PCB manufacturers often have graphic symbols and the number of electronic components, but only the components mounted on the surface of the al-based PCB manufacturer are provided with graphic symbols and Numbers.

Meet the Dream Team

Textile inspires and equips people to accelerate sustainable practices in the textile value chain. We focus on minimizing the harmful impacts of the global textile industry and maximizing its positive effects.

There has been a huge change in the electronics industry in aluminum substrates, which has greatly promoted the substitution of electronic products. The circuit board has many unique features and advantages, including several points.

The various components in the circuit can achieve electrical connections between wiring, aluminum substrate rather than complex. Reduces the workload in traditional wiring, simplifies the assembly, welding and debugging of electronic products.

In order to reduce the volume, reduce the product cost. Electronic equipment with aluminum substrate to improve quality and reliability.