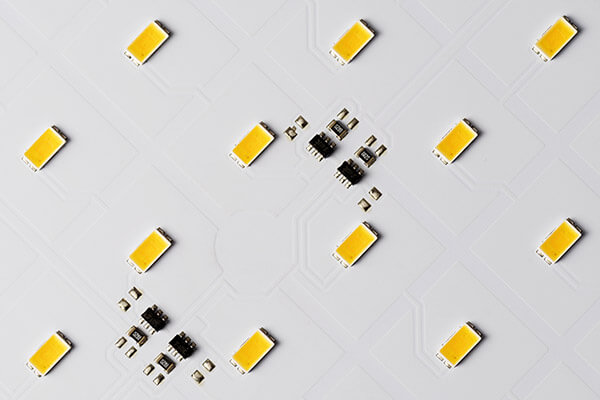

LED PCB

As printed circuit board technology has continued to evolve, it has paved the way for the creation of a host of exciting product innovations. A prime example is the development of the PCB for LED lighting. The LED is soldered to the circuit board and features a chip that produces the light when electrically connected. A thermal heat sink and a ceramic base are used to bond the chip.

Now SMD packaging type is the most widely used packaging form in LED applications. In general, it’s limited for the light emitted from a single LED component. So multiple LED components would be used for a single light fixture to achieve sufficient light. Like other semiconductor devices, PCB is the best method to electrically connect the LED components. And a PCB with LED components soldered is usually called as “LED PCB”.

If leds are integrated into a circuit board, it is easier to combine LED thin-film switches with keyboards, touch screens and other types of thin-film switches. Even when creating complex backlit switch components, built-in or embedded LED PCBS provide greater design freedom. The small thickness of LED film switches reduces the total area of these complex switch interfaces. Designers and engineers often choose integrated LED PCBS when checking and updating products.

In general, LED PCBS provide the most convenient backlight for membrane switches. Sometimes they are a better choice for small ICONS and symbols for backlighting, as larger ICONS and even backlighting with embedded LED PCB circuitry are not so easy to achieve.

Consumer Electronics

Consumer electronics are those devices that are being used by humans on a daily basis. These electronics include smartphones and computers, in fact, even the new forms of fridges also have electronic components in them. The best part about the LED PCBs is that they offer low units per cost which make the price of the final product relatively less than what it’s supposed to be.

Medical

Lighting tools used in surgeries and medical examinations commonly use high-powered LED lights, and these LED lights often use aluminum PCBs.

This is primarily due to the durability and heat transfer capabilities of aluminum PCB LEDs — this ensures medical equipment is functioning properly regardless of the number of patients cycling through a medical office. In addition to lighting tools, medical scanning technology often uses aluminum PCBs as well.

Meet the Dream Team

Textile inspires and equips people to accelerate sustainable practices in the textile value chain. We focus on minimizing the harmful impacts of the global textile industry and maximizing its positive effects.