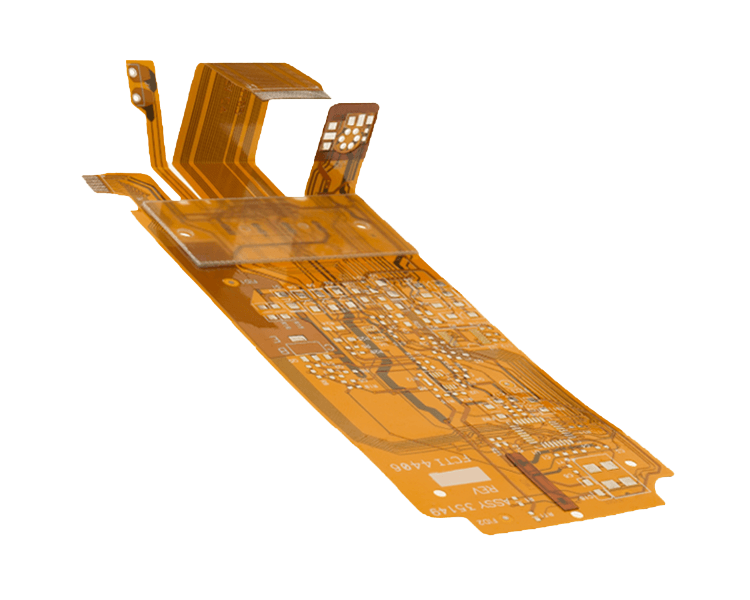

The protective coating film of rigid printed circuit boards is a solder mask, and that of flexible PCBs is coverlay. This article will give a full introduction to the coverlay of flexible PCBs, including its materials, colors, thicknesses, and frequently asked questions about flexible PCB coverlay.

Part 1: What is Flexible PCB Coverlay

Coverlay is the protective film of flexible PCBs, which plays the same functions as the solder mask of rigid PCBs:

- Insulate the copper foil (RA copper or ED copper) from the air and protect it from oxidation

- Cover the bare areas and circuit traces and protect them from soldering

- Prepare for surface finishes to PCB pads

Coverlay is insulating resin, and typical coverlay materials are polyimide (PI) and transparent polyester (PET). It has excellent dielectric properties and abrasion resistance, and flex PCBs can be used in aerospace, defense, medical, and precise electronics fields.

Coverlay includes a PI or PET film and an adhesive layer. The adhesive is brushed on the PI or PET film and then laminated under high temperatures and pressures, and a flexible PCB coverlay is formed.

Flexible PCB PI film coverlay can have the color yellow, white, or black. PET film coverlay is transparent.

During flexible PCB manufacturing, the coverlay is laminated with copper foil first, and then the other side of the copper is etched to generate circuit traces.

Part 2: Flexible PCB Coverlay Thicknesses

The thicknesses of PI/PET, adhesive, and copper decide the thickness of the flexible PCB. What thicknesses of them are available from the flexible PCB supplier?

Available PI thicknesses:

- 12.5μm,

- 25μm,

- 50μm,

- 75μm

Available adhesive thicknesses:

20μm

Available RA/ED copper thicknesses:

- 12μm,

- 18μm,

- 35μm (1oz),

- 70μm (2oz),

The minimum flexible PCB thickness from bgpcba is 2.36mm. Besides, you can have transparent PET flexible PCBs manufactured by bgpcba.

By ordering flexible PCBs from bgpcba, you can enjoy these benefits:

-

- One-stop flexible PCB fabrication and assembly from prototype to bulk production

- One-on-one engineering support and design assistance throughout your project

- Strong manufacturing capabilities – FPC from 1 to 10 layers, single-sided, double-sided

- If you need flexible PCB design, our CAM engineer with more than 20 years of experience can also help

- Free complete FPC sample and functional jig testing for bulk production

If you have inquiries about flexible PCBs/PCBA, coverlay, or laminates, please feel free to email bgpcba at sales@bgpcba.com to get a quote.

Part 3: Flexible PCB Coverlay vs PCB Solder Mask

Though coverlay and solder mask both insulate and protect the circuit, they are made of different materials and have different characteristics.

- PI and PET coverlay is made of insulating resin, which is non-photosensitive. While the PCB solder mask is made of UV-photosensitive ink.

- Flexible PCB coverlay can be bent without harm, while PCB solder mask has poor flexibility.

- The color of the PCB solder mask can be green, black, white, red, blue, yellow, pink, purple, etc. While the typical color of flexible PCB coverlay is yellow, black, or white.

Frequently Asked Questions about Coverlay of Flexible PCBs

Question 1. In flexible PCB fabrication, is the opening on the PI film coverlay in the same shape and size as the design, or should I change the design according to your fabrication capability?

If you have FPCs manufactured from bgpcba, you don’t have to change your design.

Usually, in the PCB design, the opening shape is square or rectangular. But most fabricators will require you to change it to be oval because their factories adopt the mechanical drilling method.

bgpcba provides two drilling options: mechanical drilling and punching. By punching, the opening on the coverlay is square or rectangular and the same as your design.