Aluminum PCBs are a type of printed circuit board (PCB) that use an aluminum substrate instead of a traditional fiberglass substrate. The aluminum substrate provides excellent heat dissipation properties, making aluminum PCBs ideal for high-heat-generating electronic devices. The aluminum substrate also has a low coefficient of thermal expansion, which means it does not expand or contract significantly with changes in temperature. This makes aluminum PCBs more stable and reliable than other types of PCBs.

Advantages:

1.Heat dissipation: One of the most significant advantages of aluminum PCBs is their excellent heat dissipation properties. The aluminum substrate quickly dissipates heat away from high-heat-generating electronic components, reducing the risk of damage to the components and increasing the lifespan of the device.

2.Durability: The aluminum substrate is more durable than traditional fiberglass substrates, making aluminum PCBs more resistant to physical damage and moisture.

3.High electrical conductivity: Aluminum is an excellent conductor of electricity, providing excellent electrical conductivity for the PCB.

Design flexibility: Aluminum PCBs can be designed to be flexible, allowing them to bend and conform to the shape of the device they are being used in. This design flexibility makes aluminum PCBs ideal for use in applications where space is limited.

Applications:

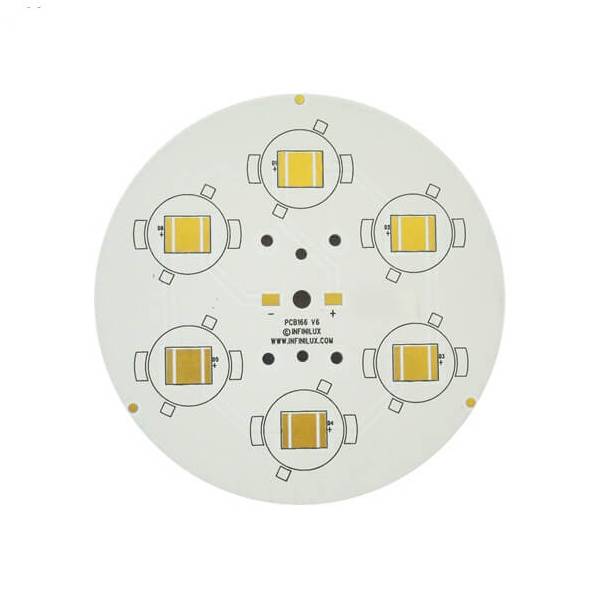

1.High-power LED lighting: Aluminum PCBs are commonly used in high-power LED lighting applications. The heat generated by high-power LEDs can damage the components and reduce their lifespan, making the excellent heat dissipation properties of aluminum PCBs essential for these applications.

2.Power electronics: Aluminum PCBs are commonly used in power electronics applications, such as power supplies and motor drives. The high electrical conductivity of aluminum and its ability to dissipate heat make it an ideal material for these applications.

3.RF/Microwave circuits: Aluminum PCBs are also commonly used in RF/Microwave circuits, where the low coefficient of thermal expansion of aluminum is essential for maintaining stable performance under varying temperatures.

4.Automotive industry: The durability and resistance to physical damage and moisture of aluminum PCBs make them ideal for use in the automotive industry.

What kind of the aluminum pcb

1.Aluminum PCB Prototype: An aluminum PCB prototype is a sample or test version of an aluminum PCB that is built to check its design, functionality, and performance before mass production. The aluminum substrate provides excellent heat dissipation properties, making it ideal for high-heat-generating electronic devices. Aluminum PCB prototypes are commonly used in high-power LED applications, power electronics, and RF/microwave circuits. The prototype can be made using the same or similar manufacturing processes, materials, and components that will be used for the final product.

2.Flexible Aluminum PCB Board: A flexible aluminum PCB board is a type of aluminum PCB that is designed to be flexible, allowing it to bend and conform to the shape of the device it is being used in. These PCBs are commonly used in applications where space is limited, and the PCB needs to be shaped to fit around other components.

3.Hybrid Aluminum PCB Board: A hybrid aluminum PCB board is a type of PCB that combines aluminum substrate with other materials, such as FR4, ceramic, or polyimide. These hybrid PCBs are commonly used in high-heat-generating electronic devices, as they offer excellent heat dissipation properties while also providing other benefits, such as increased flexibility or improved durability.

4.Single Layer Aluminum PCB: A single layer aluminum PCB is a type of PCB that has only one layer of conductive material on the aluminum substrate. These PCBs are commonly used in simpler electronic devices where only a few components need to be connected.

5.Double-Sided Aluminum PCB: A double-sided aluminum PCB is a type of PCB that has conductive material on both sides of the aluminum substrate. These PCBs are commonly used in electronic devices where more components need to be connected than can fit on a single layer.

6.Multilayer Aluminum PCB Board: A multilayer aluminum PCB board is a type of PCB that has multiple layers of conductive material on the aluminum substrate, separated by insulating layers. These PCBs are commonly used in complex electronic devices where a large number of components need to be connected and multiple layers of conductive material are required.

7.Plating Through-Hole Aluminum PCB: A plating through-hole aluminum PCB is a type of PCB that has conductive material that extends through holes in the aluminum substrate, allowing the PCB to connect components on both sides. These PCBs are commonly used in electronic devices where space is limited and components need to be connected on both sides.

8.China Aluminum PCB Assembly: China aluminum PCB assembly refers to the process of assembling aluminum PCBs in China. China is a leading manufacturer of PCBs, including aluminum PCBs, and many companies choose to outsource their PCB assembly to China due to the lower cost of labor and materials. China aluminum PCB assembly may involve the production of prototypes, single-layer or double-sided PCBs, or multilayer PCBs, depending on the needs of the customer. The process typically involves assembling components onto the aluminum PCB using surface-mount or through-hole technology, testing the functionality and performance of the PCB, and then delivering the finished product to the customer.